A Geer type aging oven (forced air circulation heat aging oven) is used to evaluate the heat aging properties of polymers, such as plastics and rubber, by heating test specimens to accelerate aging. Heat exposure is a primary cause of deterioration in polymers. However, many electronic applications such as televisions and computers, and mechanical products such as vehicles, generate heat during operation. Deterioration caused by such heat can jeopardize product liability. Therefore, it is necessary to evaluate the heat aging properties of each material.

Overview

Table of Contents

The test specimen is hanged in a chamber set at the specified temperature, and then exposed to heat for a specified period to accelerate the aging process. The specimen is then visually evaluated and its physical properties are measured (such as via tensile tests) to evaluate its heat-aging properties.

Mechanism

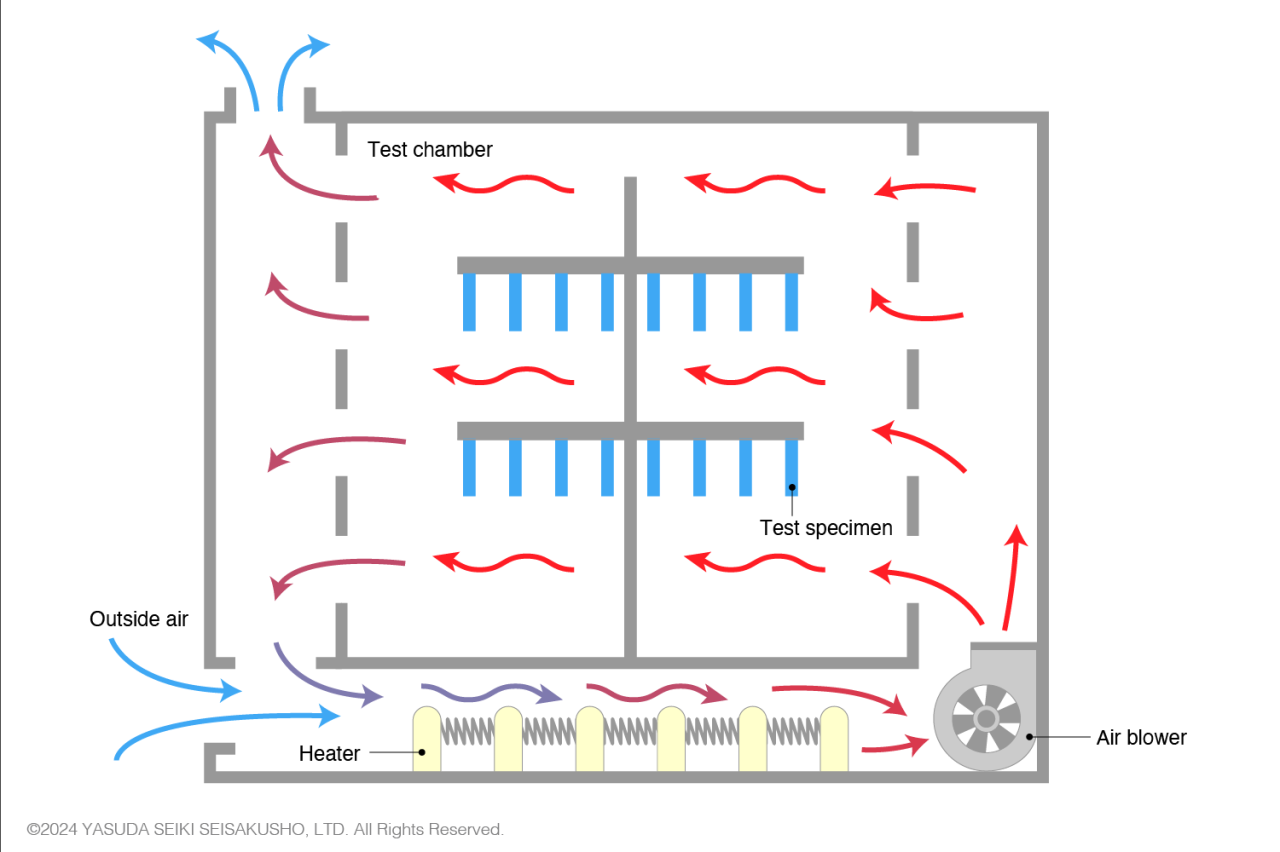

Conceptual Diagram of Geer Type Aging Oven

The oven is equipped with a “forced air circulation type” heating chamber which replaces the air inside the test chamber a specified number of times per hour. The oven consists of a test chamber, a ventilation fan, air inlet/outlet damper, temperature controller, and specimen hanger.

- Test ChamberThe test chamber is equipped with test specimen hanger (or a rack) that does not interfere with the air circulation, and is fit with thermal insulators to maintain the test chamber temperature and block out outside air.

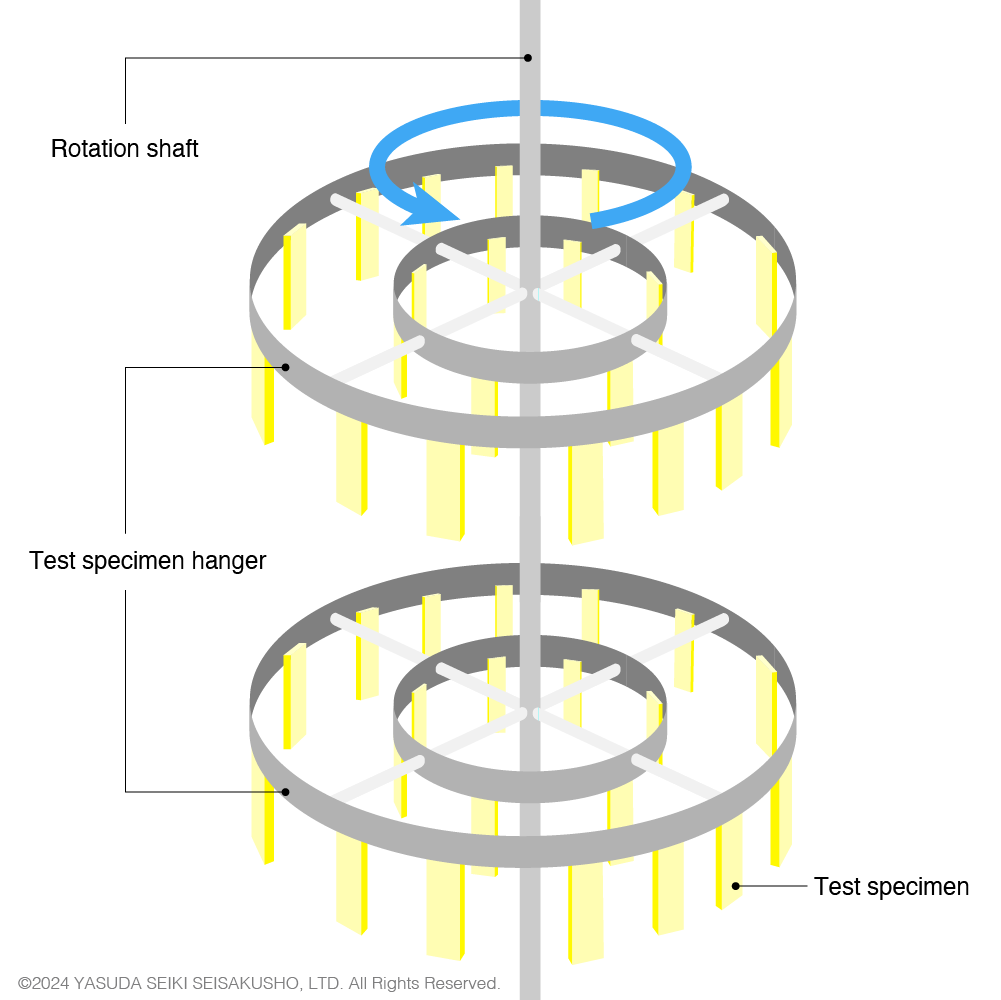

- Test Specimen HangerA single-shaft rotating hanger that rotates 5 to 10 times per minute.

Example of Single-shaft Rotating Frame

Specifications

Each standard requirements are listed as the following:

| Standard | JIS B 7757 | JIS K 6257 | JIS K 7212 | ISO 188 | ISO 4577 | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Model | Type Ⅰ | Type Ⅱ | Type Ⅲ | Crosswind type | Range wind type | A type | B type | Crosswind type (Method A) |

Range wind type (Method B) |

– |

| Air Exchange Rate (Times/hour) | 3 to 10 | 5 to 20 | 100 to 200 | 3 to 10 | 3 to 10 | 1 time per minute or more | 3 to 10 | 3 to 10 | 3 to 10 | 6 |

| Average wind speed (m/s) | 0.5±0.1 | – | – | 0.5±0.1 | 0.5 to 1.5 | 1±0.2 | 0.5±0.1 | 0.5±0.25 | 0.5 to 1.5 | 0.75 to 1 |

| Time constant | – | 660 or less | 660 or less | – | – | – | – | – | – | – |

| Specific heat (J/g-K) | 1.003 | 1.003 | 1.003 | 1.006 | 1.006 | 1.003 | 1.003 | – | – | – |

| Temperature settings range | Ambient temperature + 20℃ and 300℃ | – | – | – | Ambient temperature + 20℃ to 300℃ | – | – | Up to 200℃ | ||

| Temperature control accuracy | Set temperature ±1℃ | – | – | Up to 100℃:±1℃ 125 to 300℃:±2℃ |

Set temperature ±1℃ | Up to 100℃:±1℃ 125 to 300℃:±2℃ |

– | |||

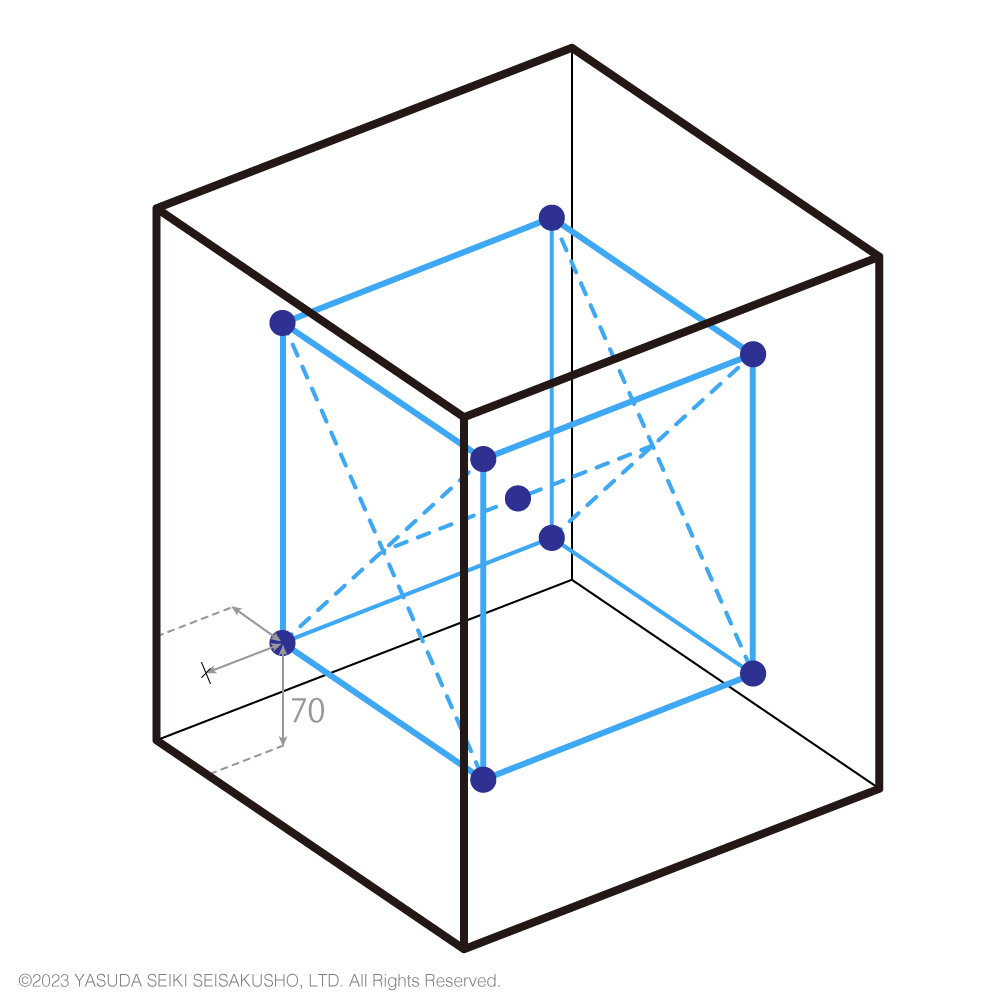

Temperature Distribution

Temperature distribution is expressed as the difference between the maximum and minimum temperatures at nine locations special points, which are specified in the standard.

Acceptable temperature distribution is defined as the following:

| Test temperature T (℃) | Temperature distribution (℃) |

|---|---|

| T ≦ 100 | 2 or less |

| 100 < T ≦ 200 | 4 or less |

| 200 < T ≦ 300 | 6 or less |

Measurement Method

Temperature Distribution Measurement Points

The temperature distribution is measured at eight vertices of a cube formed by planes located 70 mm inside from each wall of the test chamber, and at one additional point at the center of the test chamber, making a total of nine locations. After the temperature is sufficiently stable, the temperature is measured at the nine points for 24 hours, and the difference between the highest and lowest temperatures is obtained. Fluctuations in the ambient temperature over a period of 24 hours must be ±10℃ or less of the set temperature and within ±5% of the set temperature.

*Many “ovens” in the market do not satisfy the above standard requirement, and awareness of these points are important if testing according to the test standards is required.

Test Conditions

Test conditions depend on the test specimen material, and its correlating standard used in the test.

Furthermore, the test conditions are described as the following in each standard:

- JIS K 6257 (Rubber)The time and temperature is selected from a list specified in JIS K 6250, depending on the type of rubber.

- JIS K 7212 (Plastics)Temperature at which the specimen ages within the appropriate test period is selected.*The test time is not clearly specified.

Test Type (JIS K 6257 Rubber/ISO 188)

There are two types of tests: Accelerated aging test (At method) and Heat resistance test (Hr method).

- Accelerated Aging TestIn this test, the specimen is tested at higher temperatures than the actual usage conditions, to recreate the effects of natural aging in a short period.

- Heat Resistance TestIn this test, the specimen is tested at temperatures similar to what the specimen will actually be exposed to, under actual usage conditions.

Evaluation

For Rubber

The physical properties of the test specimen are measured after the aging process is complete. Then, the change from the pre-aging value is calculated to examine the heat-aging characteristics.

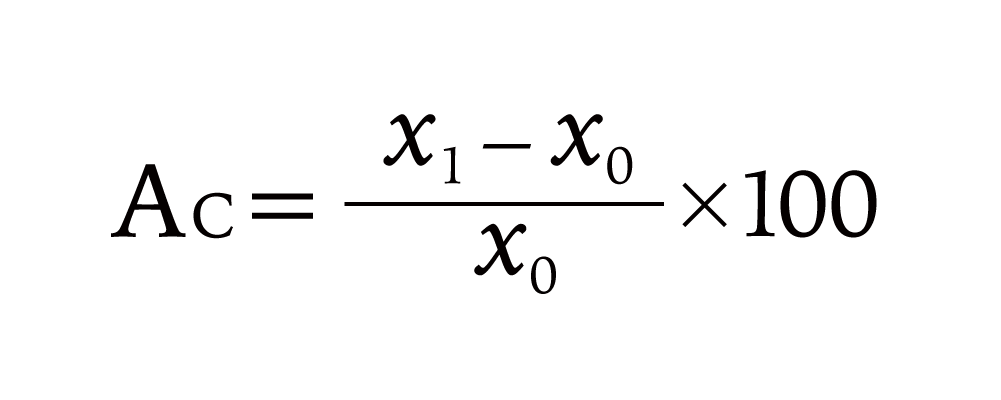

The rate of change in the physical properties other than hardness is calculated by using the following formula.

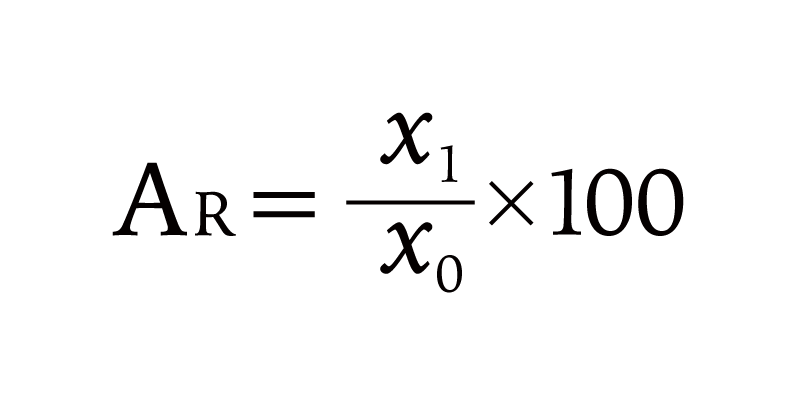

The retention rate is calculated by using the following formula.

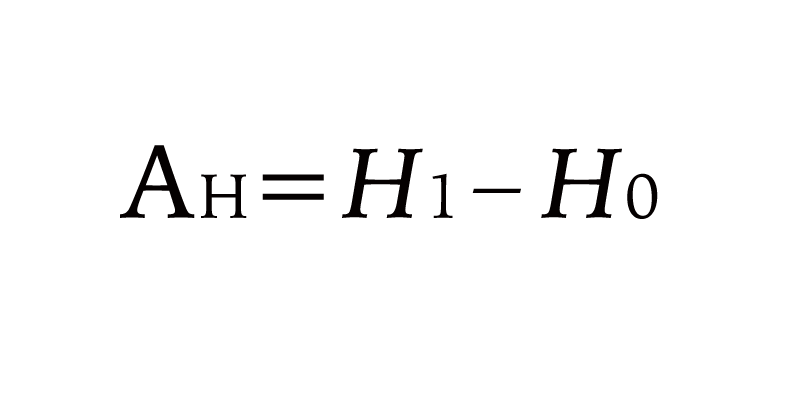

Hardness is calculated by using the following formula.

- AC:Rate of change after aging compared to the physical properties before aging

- AR:Retention rate after aging compared to the physical properties before aging

- X0:Median physical properties before aging

- X1:Median physical properties after aging

- AH:Change in hardness

- H0:Median hardness before aging

- H1:Median hardness after aging

For Plastic

JIS K 7212 states that results are judged “based on the degree of change in the properties of the test specimen after a specified period, or the time it takes for the properties to reach the specified value.”

The criteria to determine aging depends on the concerned parties; however, the criteria to determine aging is often evaluated with the following methods.

- Visual observation (instances such as powder formation, cracks, and deformation on the test specimen)

- Change in mass

- Decreased performance in tensile tests, bending tests, etc.

- Decreased optical performance such as fading

- Decreased electric resistance performance such as dielectric strength and insulation resistance

Air Exchange Rate

The air exchange rate indicates the number of times air is replaced per hour, and is determined by the airflow rate into the test chamber and the capacity of the test chamber. The airflow is measured indirectly by the “power consumption method” and directly by the “flowmeter method.” The commonly used “power consumption method” is explained below.

Power Consumption Method

The difference between “the amount of electricity required to close the air inlet/outlet and maintain the chamber at a specified temperature with the air inlet/outlet sealed” and “the amount of electricity required to maintain the same temperature when the air inlet/outlet is opened” is measured in the power consumption method to calculate the amount of exchanged air.

[Measurement Method]

- Close the air inlet, the outlet, and the safety cover, and seal the gaps with an adhesive tape. Completely block off the air inside the test chamber from the outside.

- Start the fan and raise the ambient temperature inside the chamber to +80±2℃.

- Measure the power consumption for at least 30 minutes after the temperature stabilizes (after approximately 3 hours).

- Open the air inlet and outlet, and calculate the power consumption during ventilation.

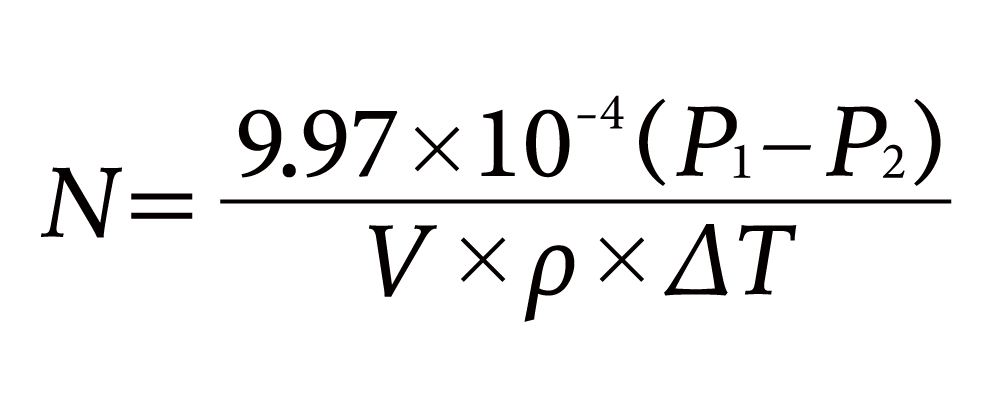

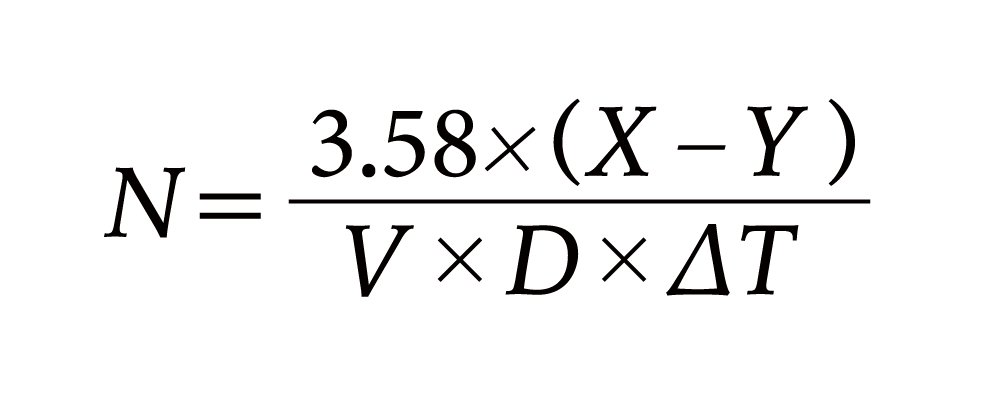

The air exchange rate is calculated with the following formula.

However, in the case of JIS K 6257, the rate is calculated by using the following formula.

The formulas for calculating the air exchange rate are different for the plastic standard (JIS K 7212) and the rubber standard (JIS K 6257) as these standards use different units for specific heat at constant pressure and power consumption.

What is UL Standard?

UL746B is the UL standard for long-term heat resistance. The heat resistance of plastics, when exposed to high temperatures for long periods of time, is called “long-term heat resistance.” Aging and deterioration due to heat can cause the physical properties of plastics to degrade. The Relative Thermal Index (RTI) of UL746B is often used as an indicator of long-term heat resistance, and the tensile strength, impact strength, and electrical insulation properties are evaluated respectively after exposure to high-temperature environments for long periods of time.

*Our No.102 Gear Aging Tester complies with this standard.

Details of the Standard

It is stated in UL746B that the test method must comply with ASTM5374 and the equipment must comply with the standard specifications of ASTM 5423 Type 1.

[Air Exchange Rate]

The air exchange rate in each standard is described as follows.

- ASTM5423At 100℃ or the maximum operating temperature, Type 1 ovens must have an air exchange rate of 5 to 20 times/h, and Type 2 ovens 100 to 200 times/h.

- ASTM5374Measure the air change rate at the maximum operating temperature and 100±2℃.

Usually, tests are conducted at four temperature points. The temperature is set such that the endpoint* is at least 500 hours at the highest temperature, and at least 5000 hours at the lowest temperature. The RTI is calculated based on the test results.

*Endpoint: Time when the physical properties degrade by 50% or less

*Heat deflection temperature (HDT) can be used as a reference. See Yasuda Seiki’s No.148-HD Heat Distortion Tester page for short-term heat resistance evaluation.

Standards

Heat aging tests and their test methods are standardized in both JIS (ISO) and ASTM standards respectively.

| Standard | Year | Applicable to | Standard name | |

|---|---|---|---|---|

| JIS | B 7757 | 1955 | Apparatus | Forced air circulation oven type thermal accelerated aging testers |

| K 6257 | 2017 | Rubber | Rubber, vulcanized or thermoplastic-Determination of heat ageing properties | |

| B 7757 | 1955 | Plastic | Plastics−Determination of thermal stability of thermoplastics−Oven method | |

| C 3005 | 2014 | Electric wire | Test methods for rubber or plastic insulated wires and cables | |

| ISO | 188 | 2023 | Rubber | Rubber, vulcanized or thermoplastic – Accelerated ageing and heat resistance tests |

| 4577 | 2019 | Plastic | Plastics – Polypropylene and propylene – copolymers – Determination of thermal oxidative stability in air – Oven method |

|

| ASTM | E145 | 2019 | Testers | Standard Specification for Gravity – Convection and Forced – Ventilation Ovens |

| D5423 | 2023 | Insulation | Standard Specification for Forced – Convection Laboratory Ovens for Evaluation of Electrical Insulation | |

| D5374 | 2012 | Insulation | Standard Specification for Forced – Convection Laboratory Ovens for Evaluation of Electrical Insulation | |

| UL | 746B | 2013 | – | Standard for Polymeric Materials – Long Term Property Evaluations |

| IEC | 60216-4-1 | Insulation | Electrical insulating materials – Thermal endurance properties – Part 4-1:Ageing ovens – Single – chamber ovens |

|