GEER TYPE AGING OVEN YASUDA SEIKI No.102

A Geer type aging oven (forced air circulation heat aging oven) is used to evaluate the heat aging properties of polymers, such as plastics and rubber, by heating test specimens to accelerate aging. Heat exposure is a primary cause of deterioration in polymers. However, many electronic applications such as televisions and computers, and mechanical products such as vehicles, generate heat during operation. Deterioration caused by such heat can jeopardize product liability. Therefore, it is necessary to evaluate the heat aging properties of each material.

The test specimen is hanged in a chamber set at the specified temperature, and then exposed to heat for a specified period to accelerate the aging process. The specimen is then visually evaluated and its physical properties are measured (such as via tensile tests) to evaluate its heat-aging properties.

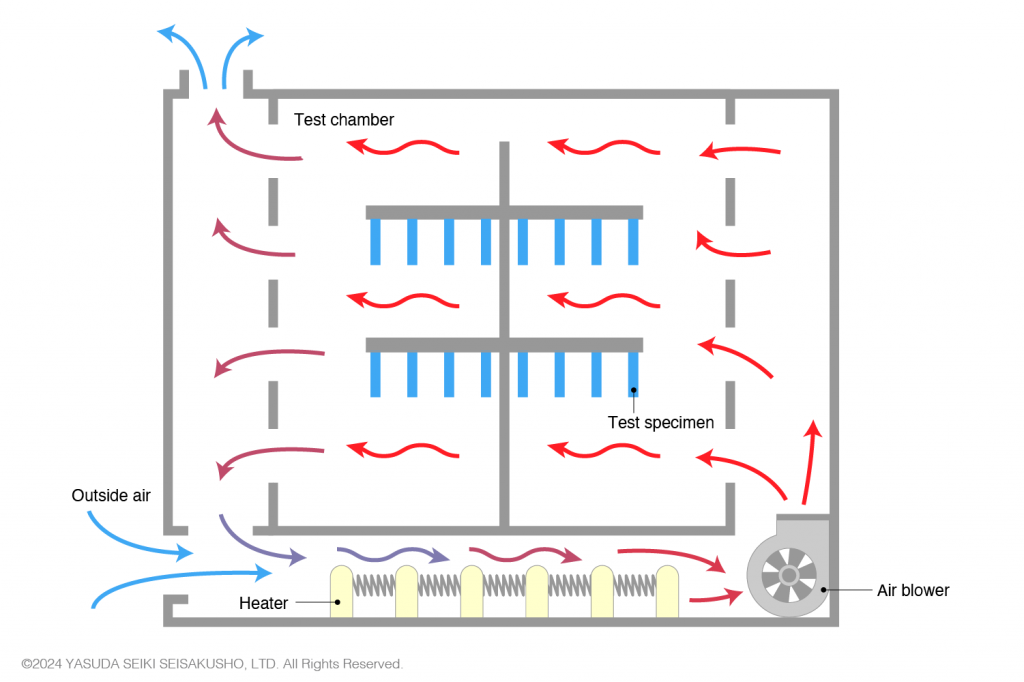

Mechanism:

The oven is equipped with a “forced air circulation type” heating chamber which replaces the air inside the test chamber a specified number of times per hour. The oven consists of a test chamber, a ventilation fan, air inlet/outlet damper, temperature controller, and specimen hanger.

Test Chamber

The test chamber is equipped with test specimen hanger (or a rack) that does not interfere with the air circulation, and is fit with thermal insulators to maintain the test chamber temperature and block out outside air.

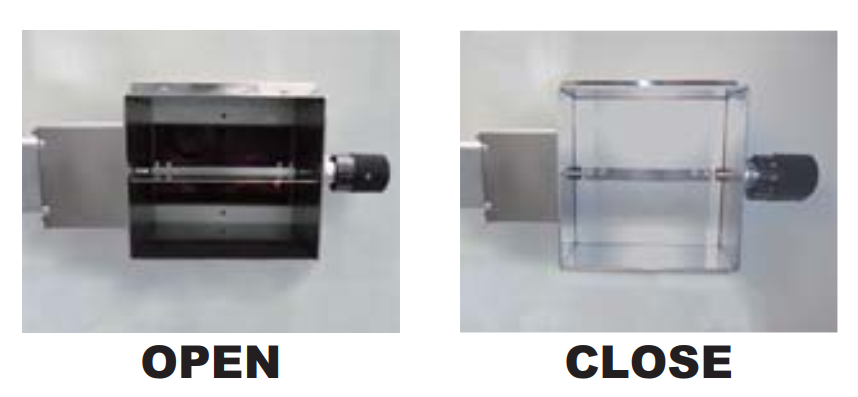

Test Specimen Hanger

A single-shaft rotating hanger that rotates 5 to 10 times per minute

Specification:

Have 2 model SHF-S and SHF-SA with 2 chamber capacity as below:

| Specifications are subject to change without notice. | ||

| Inner dimensions | W450 × D450 × H500 mm | W600 × D600 × H600 mm |

| Chamber Capacity | 225,225 cm3 | 417,600 cm3 |

| Temperature range | Room Temperature + 20 to 300 °C * | Room Temperature + 20 to 300 °C * |

| Air velocity | Low: 0.5 ± 0.1 m/s, High: 1.0 ± 0.2 m/s (Controlled vie touch panel) |

Low: 0.5 ± 0.1 m/s, High: 1.0 ± 0.2 m/s (Controlled vie touch panel) |

| Air Exchange Rate Measurement | Power Consumption Method | Power Consumption Method |

| Air Exchange Rate Control | Adjustable between 3 to 10 times/hr, 5 to 20 times/hr or over 60 times/hr | Adjustable between 3 to 10 times/hr, 5 to 20 times/hr or over 60 times/hr |

| Hanger Rotation Speed | 7.5 ± 2.5 rpm | 7.5 ± 2.5 rpm |

| Safety Device | Overheat Detection Device, Circuit Braker | Overheat Detection Device, Circuit Braker |

| Accessories | Specimen Hanger 2 stages, Clip 40 pcs, Shelf 2 pcs | Specimen Hanger 2 stages, Clip 40 pcs, Shelf 2 pcs |

| Option | CSV Output, Analog Voltage Output, Miniprinter, UL Type Air Exchange Rate 100 to 200 times/hr modification | CSV Output, Analog Voltage Output, Miniprinter, UL Type Air Exchange Rate 100 to 200 times/hr modification |

| Power source | AC 200 V, 3-Phase, 30 A, 50/60 Hz When Air Exchange Rate is 100 to 200 times/hr; AC 200 V, 3-Phase, 40 A, 50/60 Hz |

AC 200 V, 3-Phase, 40 A, 50/60 Hz |

| Dimensions/ Weight (Approx.) | SHF-S: W1,180 × D700 × H1,560 mm/ 300 kg SHF-SA: W1,250 × D700 × H1,650 mm/ 305 kg |

SHF-S: W1,350 × D900 × H1,650 mm/ 372 kg SHF-SA: W1,400 × D900 × H1,750 mm/ 375 kg |

* Please contact us for 400 °C Type.

Models

| Specifications are subject to change without notice. |

||

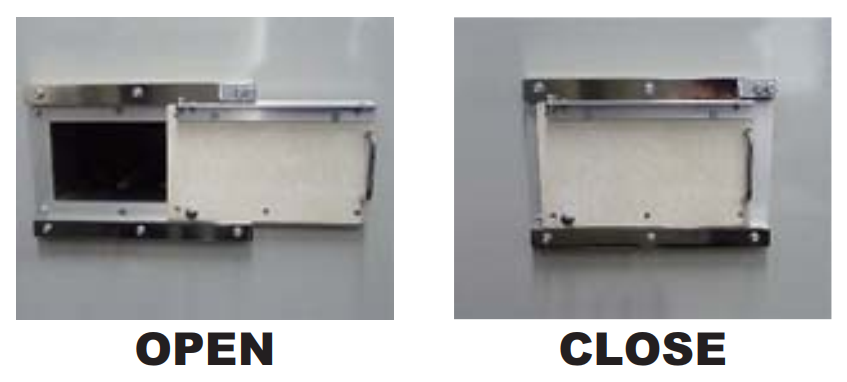

| SHF-S | Equipped with air exchange rate measurement/display via touch panel. Damper is opened/closed manually. |

|

| SHF-SA | Equipped with air exchange rate measurement/display via touch panel. Automatic Damper Control. |

|

See more:

Contact us:

Reviews

There are no reviews yet.